How we do it

What sets Absolute Machining apart is what we have under the hood. Our deep understanding of metallurgy, combined with a comprehensive arsenal of advanced tools, allows us to expertly sculpt materials, manipulate geometries, and bring virtual designs to life.

By seamlessly integrating our expertise in three-dimensional computer modeling with cutting-edge machining technology, we achieve a level of precision and transparency essential for transforming imaginative concepts into tangible, high-quality products. Our unique approach ensures that every project, whether conceived in virtual space or through intricate design, is realized with exceptional accuracy and craftsmanship.

Shop Floor

Vertical Milling Centers

Slant Turret Turning Centers

60x30 (1 Fadal)

50x20 (1 Doosan)

50x20 (2 Haas)

45x25 (1 Fadal)

30x16 (7 Haas)

SL-20T (1 Haas)

SL-20 (1 Haas)

ST-20 (1 Haas)

CoBot

Univeral Robot UR10e

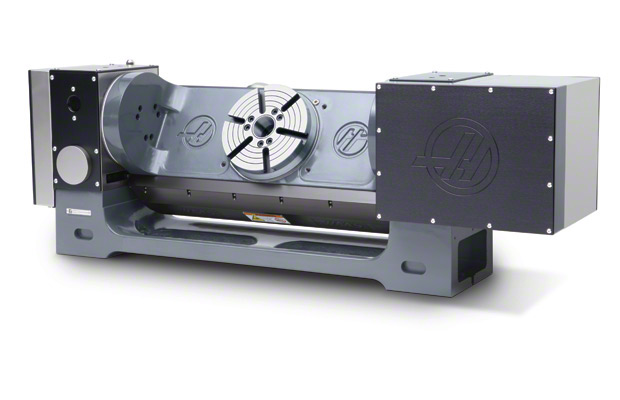

Trunnion (5th Axis Milling)

TR-210 (1 Haas)

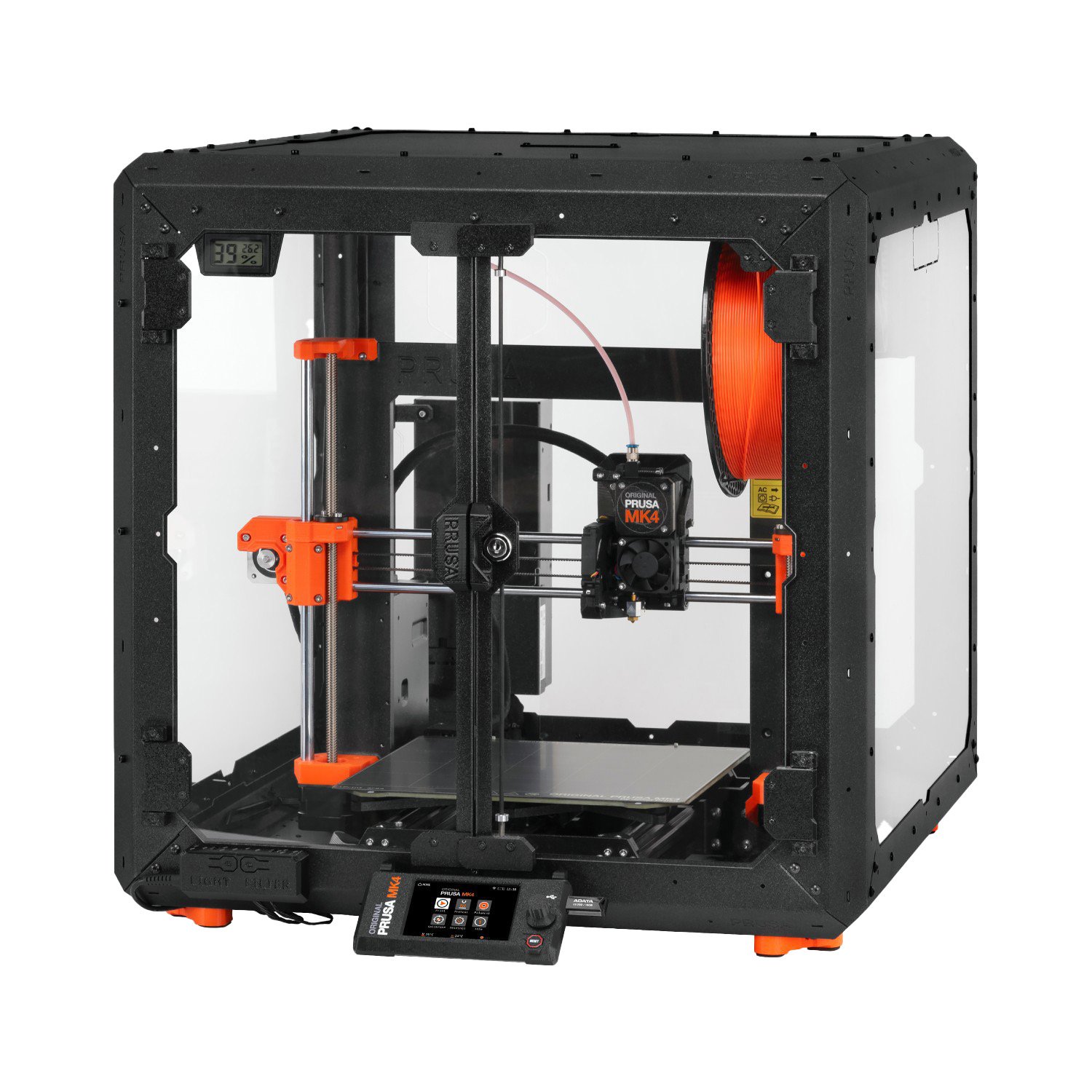

3D Printers

Prusa MK4

Bandsaws

HA250W (1 Amada)

Rutland Vertical Saw

Quality Control

Coordinate Measuring Machine

Mitutoyo CRT-EX7106T CNC CMM

Height Gauge

Dial Height Gage with Digital Counter (3 Mitutoyo)

Optical Comparator

Starrett HB 400